Modern Trade

Lifting Same store sales in modern trade

One of the world’s leading ice cream companies has been utilizing CoolR’s system of StoreAware with Vista cameras to significantly uplift performance in large format grocery stores.

The brand was looking for a 10% increase in sales using CoolR’s solutions and has achieved results close to 40% growth. And impressively, this uplift came despite the starting point being orders based on ePOS data!

The Challenge

Impulse ice cream sales depend on perfect availability every day, very much like any other product category, but the shopper mission of immediate consumption and gratification makes shoppers even more demanding. They will not go to another store in search of the desired product but simply drop the purchase or switch to another brand or even product category.

The brand identified an opportunity to improve everyday availability of their products despite ordering and replenishment being based on ePOS systems. The issue with ePOS is that it does not accurately account for low stock, slippage and the time needed for fulfilment.

The brand was clear that the most important KPI was the growth uplift vs a set of comparator stores that continued ordering based on ePOS systems.

The Solution

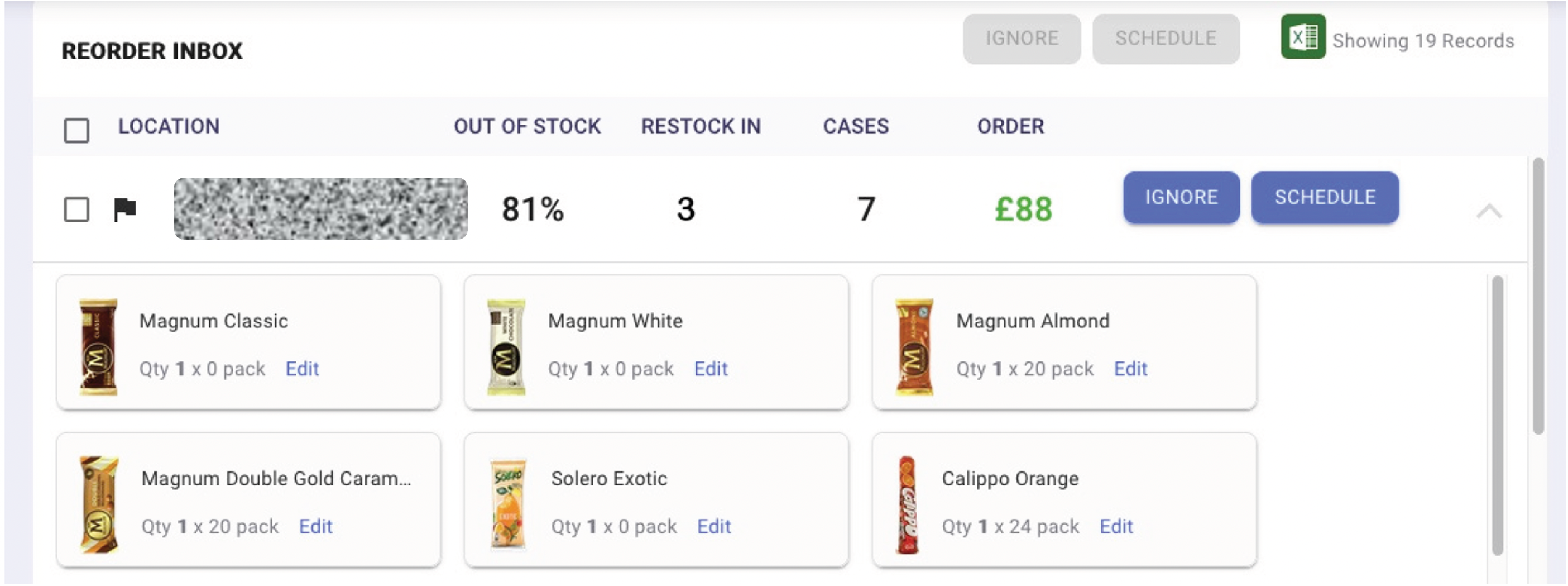

Existing freezers in the participating accounts were retrofitted with Vista cameras and connected to the StoreAware SaaS solution.

The generated orders were automatically ingested into the brand’s ordering system to ensure timely replenishment of the stores.

In this specific case the client decided to set the minimum order quantity at four cases. Any re-order need below that threshold would be ignored and only when passing this limit would an order be pushed at the daily time-slot defined by the client. All this was based on a target portfolio per store that the brand had agreed with the retailer.

The Impact

The new approach delivered an incredible growth uplift of 65% over stores re-ordering manually and 40% uplift over stores using ePOS data for ordering. The main drivers for this superlative performance were:

– StoreAware acting on every actual out-stock opportunity immediately while previously store visits suggested there was an issue but the teams had underestimated the impact

– The new data insight and collaboration between brand and retailer led to timely replenishment adjusting the process previously in place. The huge uplift did place significant strains on the fulfilment system – a luxury problem to have and to resolve.

– The brand and retailer were suddenly aware of actual on-shelf rotations and missed opportunities. This new insight was the starting point for optimization discussions on portfolio, asset strategy and roll-out of CoolR’s solutions to more stores.

When I use StoreAware, I feel like I’m in the future. This type of

Client Account Manager, Unilever

automation feels like something taken from the year 2050

The Lessons Learned

Traditional approaches to replenishment are inefficient. By acting on past sales and fixed visit routines it is most likely you miss opportunities, either over-investing in visiting stores or missing opportunities. How can you hit the bullseye when blindfolded?

Even replenishment based on ePOS data is inaccurate as it misses to account for low stock situations, for slippage and for the time-gap in fulfilment.

A strong cooperation between retailer and brand is essential. The new approach requires every party to reconsider the way of working and to accept data-based insights leading to actions.

You need the willingness to drive change management across the value chain. In this case the fulfilment of orders from warehouse to stores was the weakest link and needed the most attention to realize the obvious opportunity.

You need passionate leadership willing to change the status quo. A dedicated project with strong empowerment and sponsorship from senior leadership is a big enabler.